Bespoke Instrumentation - Case Studies

Water In Oil Detector

JK Controls have designed, developed and built

a device for detecting the interface between water and oil.

A way of detecting if

water is present beneath the waste oil and fat collected for

recycling and processing into bio-diesel was required. Our solution involved

building a device with an LED array that illuminates as the probe passes

through oil and encounters a layer of water. The device is made of

materials that resist corrosion and boiling water and can cope with a

harsh operating environment. A pair of handles are fitted for ease

of use and to aid insertion through hard fats. The detector is

battery operated, with the batteries housed in a separate compartment to

the electronics. It will switch off automatically after 20 minutes

to conserve battery life. There are internal adjustments for

changing the sensitivity (Span) of the detector and also for setting the

zero of the LED array. Click

HERE for a PDF with

further information and images.

Aircraft Wing Brake Test Rig

JK Controls have designed, developed and built

bespoke instrumentation and controls for a test stand for a prototype aerolon

brake.

The aerolon drive shaft is held by an

electrically operated brake when not required to rotate. The brake has to

bring the shaft to a halt within 40mS of being de-energised. For testing

purposes the shaft is rotated by a motor at up to 1500 rpm. The motor is

driven by a variable speed inverter at a preset speed. On de-energising

the motor, the shaft free-wheels for a few msecs and the speed is measured.

The brake is then de-energised and the shaft monitored until it ceases to

rotate. Timers automatically start and stop during the braking event.

This project required several custom designed

components where there were no suitable proprietary products available. As

the shaft stops within 40 msec. it only turns about one quarter of a turn

from running to stopped. Therefore the speed was measured using a very

fine resolution printed slotted wheel and a suitable optical detector.

Physical constraints prevented access to either end of the shaft, the slotted

disk was therefore custom made, together with the high speed optical detector by

JK Controls Ltd. Using fast hardware processing the shaft was determined

as stopped when the pulse repetition rate dropped below a threshold. The

timing and measurement logic was designed and built on to custom printed

circuits. During the braking period the brake torque is measured by a

strain gauge and the peak braking torque, in both directions, is stored.

Analogue hardwired circuits were built to sample-hold for peak torque and

initial speed stores. The stored values are displayed on suitably scaled

digital indicators.

The sequence of running up the motor, priming the

data collection and timers, initiating the test and monitoring the results was

handled by a small PLC. Various safety interlocks are built in to prevent

operation under unsafe conditions. Great care was taken to minimise

sensitivity to, and radiation of, electro-magnetic interference.

Brake Test Rig |

Occulting Disk |

Control Panel |

Peak Torque Detector |

Optical Detector |

Remote camera controls

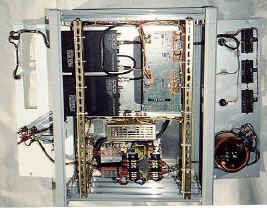

Typical console opened up

A

power plant company use many specialist techniques for plant inspections during

overhaul periods. One need was for an operator console to house the

controls and monitors. JK Controls Ltd built a pair of custom consoles

that could vary the lighting and monitor the temperatures of the cameras and

their inclination from normal within the plant. The horizontal shift of

one camera could also be altered remotely to adjust the stereoscopic imaging. A

power plant company use many specialist techniques for plant inspections during

overhaul periods. One need was for an operator console to house the

controls and monitors. JK Controls Ltd built a pair of custom consoles

that could vary the lighting and monitor the temperatures of the cameras and

their inclination from normal within the plant. The horizontal shift of

one camera could also be altered remotely to adjust the stereoscopic imaging.

JK Controls have also built bespoke control consoles for video display,

recording and camera monitoring.

Cable wrapper speed analysis

A specialty cable manufacturing company required a

measurement of deceleration of cable insulation winding heads with a time

resolution of a few milliseconds. Access to the plant was extremely

restricted. JK Controls designed and manufactured signal conditioning

equipment and a small custom transducer to run on the surface of the winding

head. The measured speed was recorded on a high speed recorder which could

indicate any non-linearity in the deceleration and any over-run of the drive

mechanism.

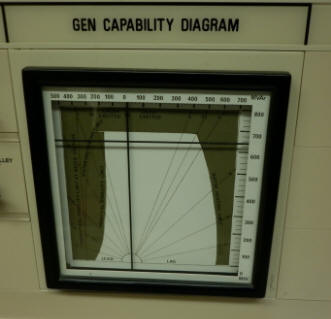

Generator loading monitor

Power station operators have to supply power to the

National Grid within very tight margins. If they run below target they

suffer penalties, but if they supply above target they do not get paid for the

excess energy. To walk this tightrope during steady running is sometimes

difficult, but to follow the moving target load after synchronizing and whilst

raising load is much more difficult.

JK Controls have built a PC based monitoring

system that enables the operator to input the type of run up and the target load

and time. This will then draw the load trajectory on the screen with

tramlines to indicate the tolerance allowed. Once synchronized, the

generator load will be plotted on this screen in real time and the operator will

endeavour to drive the plant to maintain the generator output within the

tramlines.

Retrofit Solutions - Case Studies

Legacy Alarm System Renewal

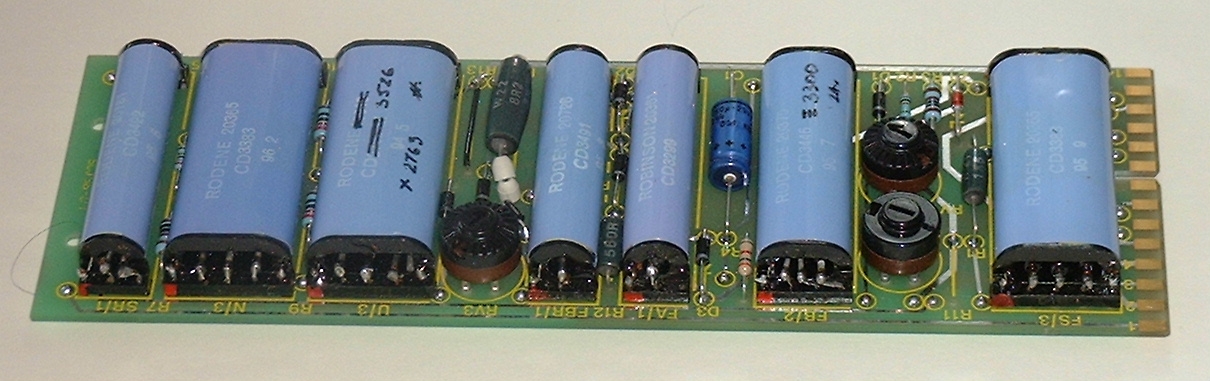

A power station's ageing alarm system

had become obsolete due to the original manufacturer no longer being in

business. JK Controls provided a cost effective solution by analysing

the existing system and then designing and building new solid-state based

circuit boards to electrically emulate and be physically plug compatible with

the original.

Original obsolete Alarm card

New plug compatible Alarm card

Vector Meter Retrofit

JK Controls have recently

designed and built modern electronic Vector Meters to replace the original

obsolete mechanical instruments in a Scottish power station. The

Vector Meters can be setup using jumpers to take either 4 - 20 mA or 0 - 10

Volt input signals. The two input signals, mega Watts and mega VArs

are galvanically isolated and displayed on a TFT screen mounted within the

operators control desk.

Original obsolete mechanical Vector Meter.

Modern replacement electronic Vector Meter.

SCADA Retrofit

JK Controls replaced an

obsolete control system

for a power station's

generator/grid switchgear within a two day outage. This was achieved by

the manufacture of custom interfacing equipment which was plug compatible with

the original system I/O connectors, thereby providing considerable cost

benefits to the station in terms of downtime and future reliability.

Virtual Chart Recorders

Ageing and obsolete control room

chart

recorders at a power station in Kent had become unreliable and expensive to

maintain. JK Controls designed and built a virtual recorder system based

upon PLC input equipment and three SCADA PC's driving twelve TFT liquid

crystal monitors. Each display emulated four multi-pen chart recorders

and was mounted in an add-on section of control desk designed by JK Controls,

which integrated with the operators original desk. The resulting

flexible data display system was provided at low cost compared to replacement

costs for the existing recorders.

Contact Information: e-mail to info@jkcontrols.co.uk,

or telephone +44 1732 522353

Registered

Address: JK Controls Ltd, The Barn, 65 High Street, East Malling, Kent, ME19

6AJ.. Reg. No.

3073964 [Top of Page]

[Control Systems Design Home Page]

|

Consultation, Design and Build - Control and Instrumentation

Consultation, Design and Build - Control and Instrumentation